Contact Us

Geosynthetics

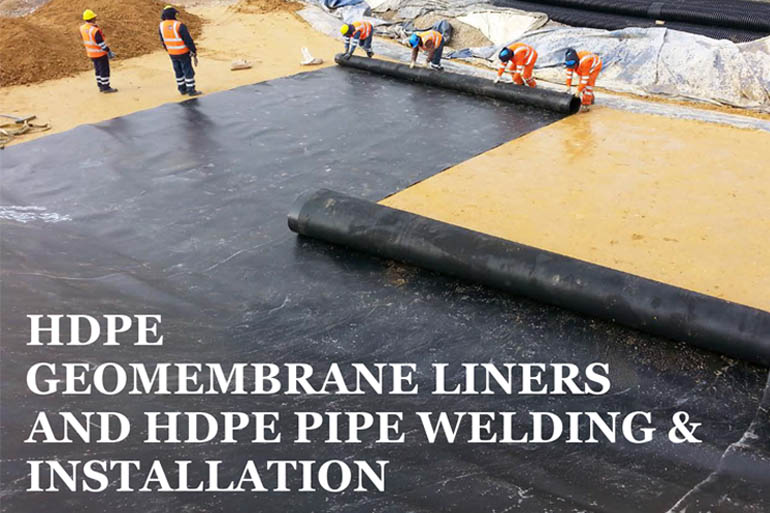

Excel Tech fabricates and installs a variety of geomembrane liners and other geosynthetic products, under strict quality control. After analyzing the site’s requirements and project specifications, the appropriate liner is selected and shipped to the site, in various sizes of geomembrane sheets, whichever is best for field installation. All installations are supervised by experienced Field Superintendents, with highly trained Technicians, and strict Quality Assurance and Quality Control. HDPE smooth geomembrane pond liner is also called smooth HDPE geomembrane, It is produced from best quality High Density Polyethylene (HDPE) material.

Installations

The above-mentioned geosynthetics are used to fabricate and install lining systems, for a variety of reservoirs, ponds, lagoons and canals. Other installations include: Tanks and Tank Farms, Methane Mitigation Systems and Barriers, Concrete Protective Liners, Waterproofing and Landfill Cells and Caps. Our systems are tailored to the requirements of the project, and the needs of our customers. Installing HDPE and LLDPE requires certified welding technicians equipped with specialized equipment to assist in deploying material and welding. Single rolls are deployed, and each seam is welded using a wedge welder which fuses the overlapping layers together.

HDPE Pipe Joining Methods

Hdpe pipe joining methods are done in 2 different ways. Hdpe Pipe is connected by Butt Welding, Electrofusion Welding or mechanical fasteners. Pipes made of materials other than polyethylene can be connected with compression fittings, flanges or other suitable adapters suitable for this purpose. Connection parts provide convenience according to the places to be used. Currently, two methods are used for joining HDPE pipes:

• Butt Welding • Electrofusion (EF) Welding

Butt Welding

The Butt welding method is the most common welding method currently used for joining hdpe pipes and fittings. The pipe joining method is a process in which the two ends of the pipes to be heated and welded by using a butt welding machine and the both ends are pushed

toward each other by pressure under a certain

temperature. Hdpe pipes up to 1200 mm in diameter can be welded by using the welding method. The butt welding method is made in

accordance with DVS 2207 standard.

Electrofusion Welding

In the electrofusion welding process, welding is done with heating resistors inside the fusion fitting. Once the pipes are placed in the Ef fittings, the ends of the welding machine are connected to the resistors of the ef fitting and heating them. So, Hdpe pipe will be connected with the electrofusion fitting. Pe 100 pipes can be welded by Electrofusion welding method with Hdpe pipes of 20 mm diameter and up to 1200 mm diameter. The electrofusion welding method is carried out in accordance with DV 2207 standard. toward each other by pressure under a certain temperature. Hdpe pipes up to 1200 mm in diameter can be welded by using the welding method. The butt welding method is made in accordance with DVS 2207 standard.

Comparison of EF Welding and Butt Welding

• Hf both weldings are made by licensed welders and in accordance with DVS 2207 standard, there is no difference in quality between the butt welding and electrofusion welding methods.

• Make sure that the right method is used in the right place to get the best performance from the work done.

• The butt welding method is more advantageous comparing to the EF welding by seeing the welding position.

• Electrofusion welding is more advantageous when it is necessary to weld in high ground or where welding machine can not fit.

• It is more advantageous to obtain the welding operation according to the degree of convenience.

• In the electrofusion welding method, the factors determining weld quality are higher than those of the butt welding (pipe ovality, electrical voltage and continuity, measurement

tolerances, etc.). Therefore, the butt welding is more advantageous than the electrofusion welding.